EUV Reticle Handling Solutions

Automatic EIP Inspection Equipment/ EUV Reticle Sidewall Inspection

Functions

The automatic EUV POD surface inspection tool is used for the semiconductor EUV process. It complies with the function of the inspection for the EIP cover and baseplate, identifying the particles and defects on the EIP surface. It is beneficial for EUV POD quality management.

- Full-auto EUV POD loading

- Automatically inspect the EIP cover and baseplate surface to control and monitor surface quality

- AI defect analysis system integrated to identify the defect sizes, defect map, and classifies them.

- SECS/GEM and E84 OHT functions available

- SECS/GEM 200/300

- Equipment Certification: SEMI S2 & Seismic Certification

EUV Lite Exchanger

Functions

We offer automated EUV reticle exchange, access, and storage between carriers with continuous nitrogen (N2) purge system to ensure the quality and cleanliness of EUV reticle storage.

- Independent purge and flow control features for each storage shelf

- SECS/GEM and E84 OHT functions available

- SECS/GEM 200/300

- Equipment Certification: SEMI S2 & Seismic Certification

EUV Reticle Exchanger

Functions

We offer automated EUV reticle exchange between RSP200 POD and EUV POD.

- POD RFID and EUV reticle barcode reading function.

- Equipped with six-axis robot which is capable of multi-angle and omnidirectional movements.

- EUV reticle picture imaging and capture function.

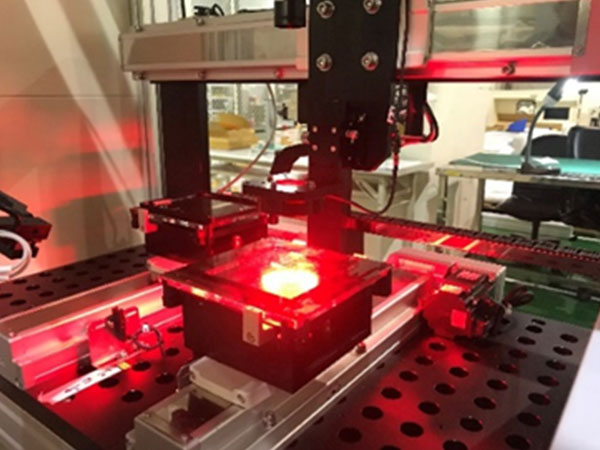

EUV Vacuum Cleaner

Functions

Cleaning through vacuum suction and XCDA air-knife blowing

- Vacuum cleaning for front side and back side of the reticle.

- Automatic reading of 1D/2D barcodes

- SECS/GEM functions available

- Equipment Certification: SEMI S2 & Seismic Certification